With ever-increasing complexity and demands in the supply chain, companies need end-to-end visibility to optimize performance from product design to distribution. Our data and analytics solutions help you make informed decisions and streamline your supply chain for improved resilience and profitability.

Data and Analytics Services for Your Supply Chain

We design and build analytics solutions to help you gain end-to-end visibility of your supply chain activity, operate leaner, and boost profitability.

Forecasting and Planning

Analyze customer data, trends, and seasonality to predict future demand. Plan production and inventory levels during specific time periods.

Transportation and Logistics

Visualize delivery plans and routing networks to shorten time from order to delivery. Analyze shipment and item data to minimize errors and control costs. Measure and track outbound deliveries and analyze warehouse productivity.

Fleet Management

Use real-time data to ensure preventative maintenance, monitor driver safety, and measure fueling costs. Get insight into driver behaviors and implement smart driver protocols.

Supplier Performance

Monitor supplier metrics to identify top and bottom performers and compare profit margins. Renegotiate contracts based on supplier performance.

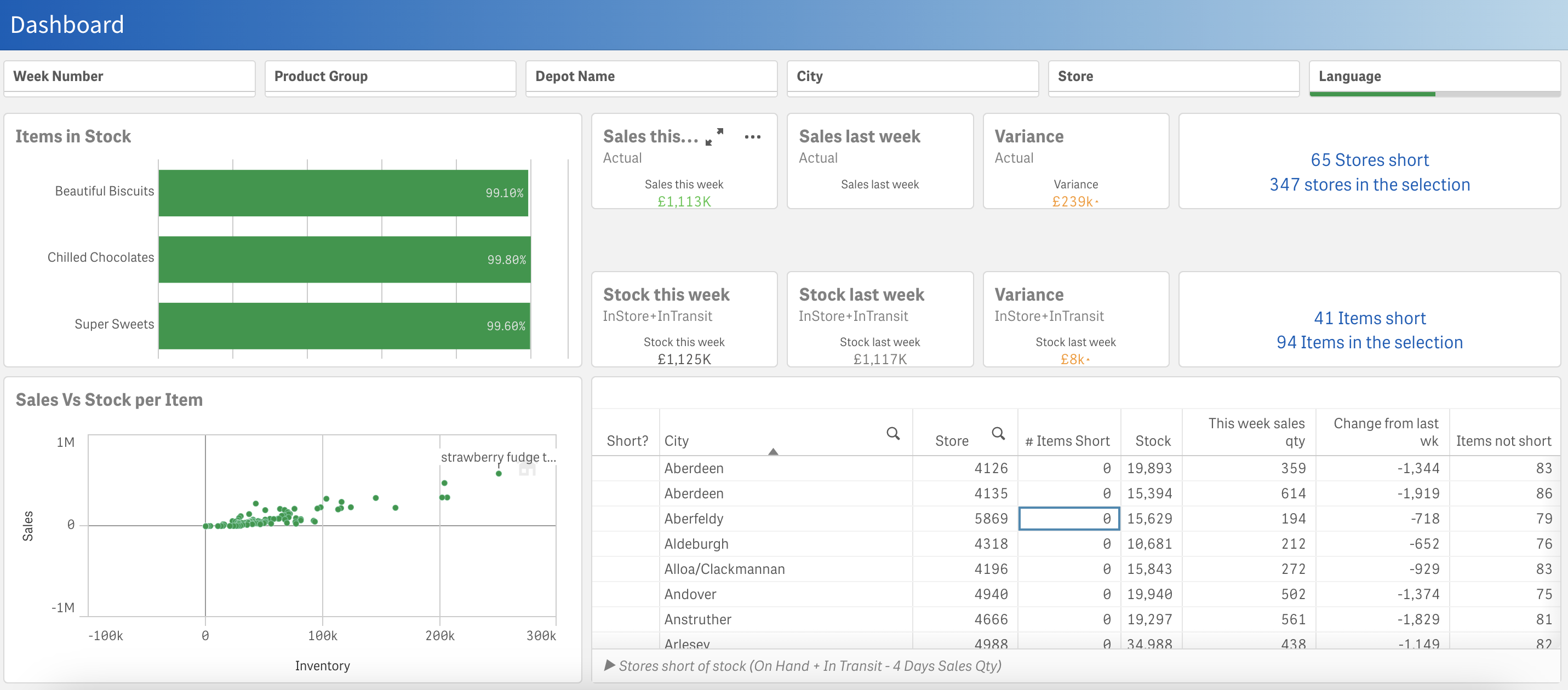

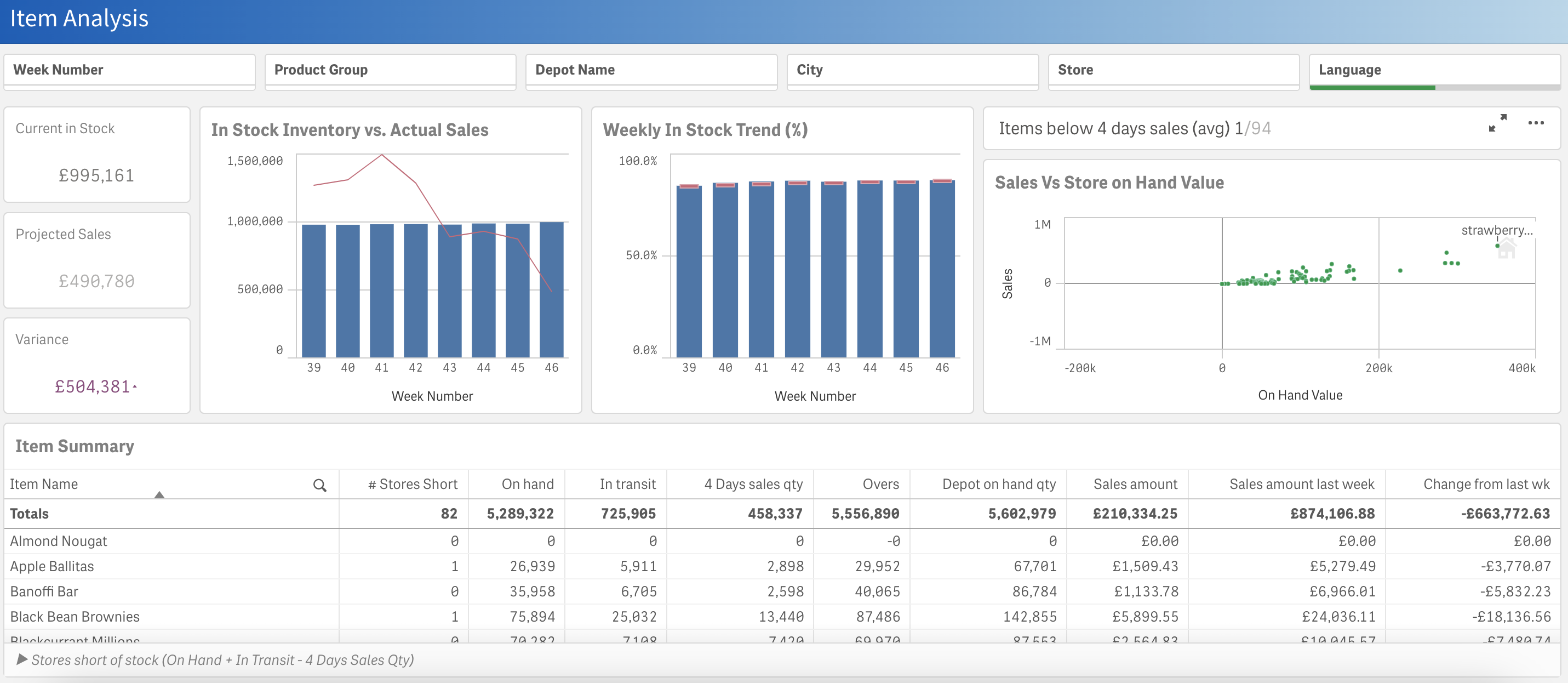

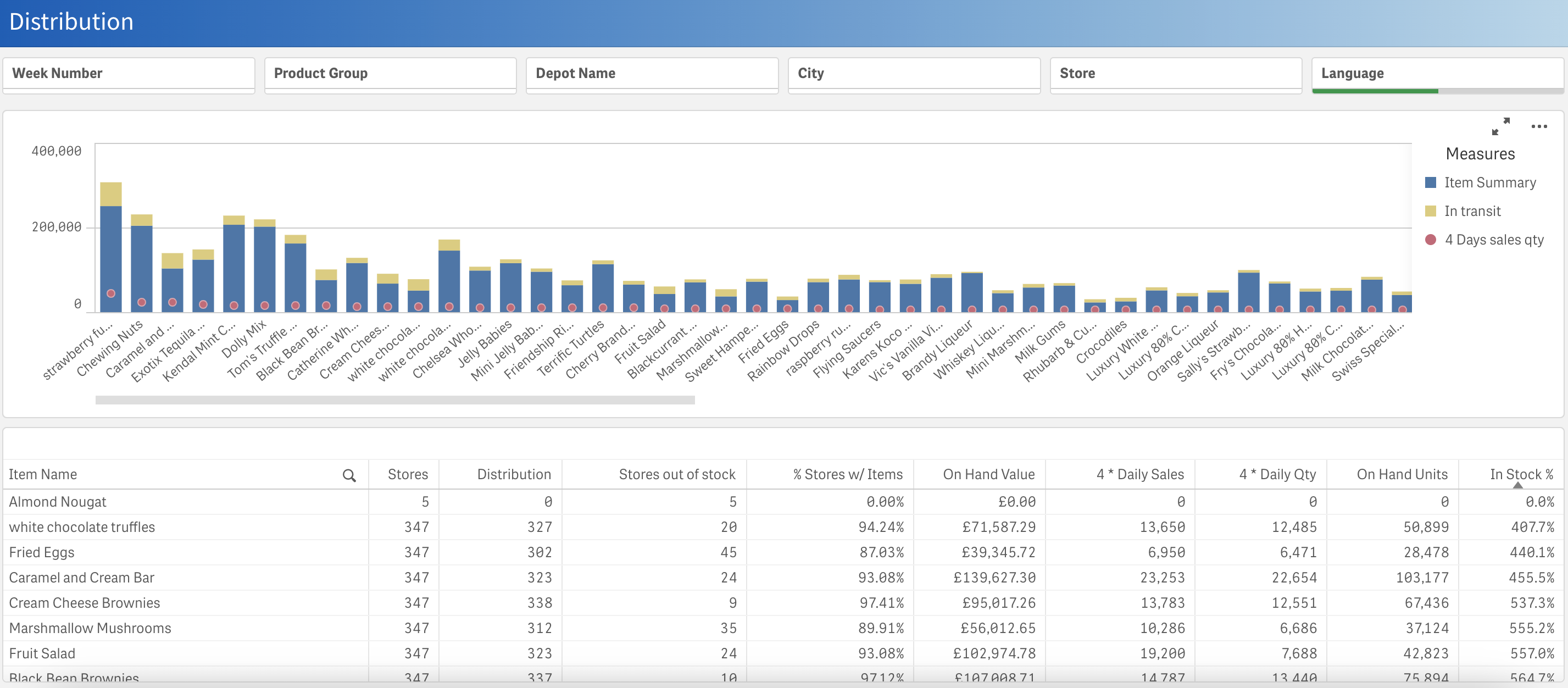

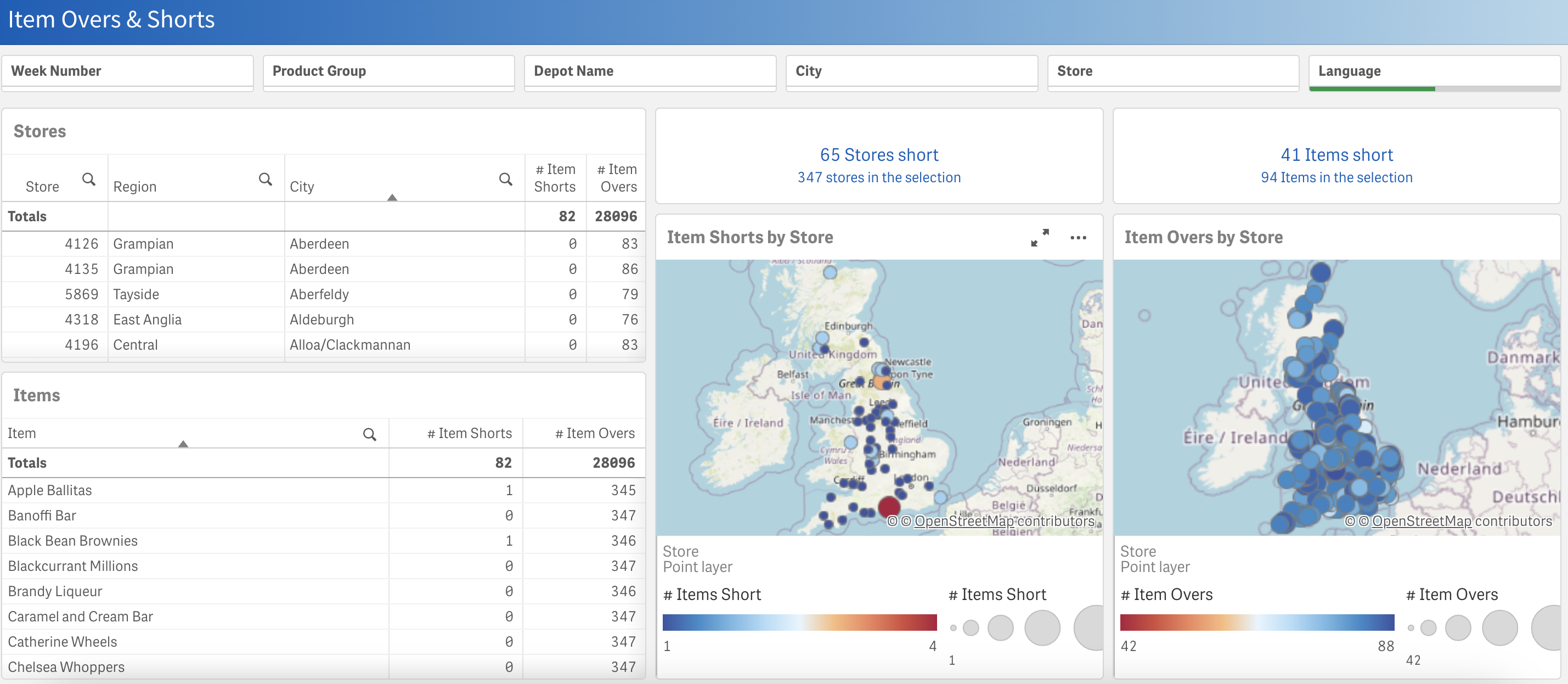

Inventory Management

Track sales-to-inventory ratio, days of inventory, total inventory, and return on inventory. Improve demand forecasting to avoid stock-outs and excess inventory.

Here are some examples of how to use BI for Supply Chain along with some KPIs for each:

Inventory management

Monitor and analyze inventory levels to optimize stock and reduce carrying costs.

KPIs include:

- Inventory turnover ratio

- Carrying cost of inventory

- Stock-out rate

- Lead time

Transportation and logistics

Analyze transportation and logistics data to optimize delivery schedules and reduce costs.

KPIs include:

- On-time delivery rate

- Transit time

- Shipment accuracy

- Cost per mile

Supplier performance

Monitor supplier performance to ensure quality and reduce costs.

KPIs include:

- Supplier delivery performance

- Quality score

- Lead time

- Cost variance

Production and planning

Analyze production data to optimize production schedules and reduce waste.

KPIs include:

- Capacity utilization rate

- Cycle time

- Yield rate

- Production lead time

BI can be used to gather data from multiple sources and provide real-time insights into these and other key areas of the supply chain, allowing companies to make data-driven decisions that can improve efficiency, reduce costs, and increase customer satisfaction.