In a highly complex and data-rich industry, manufacturers are seeking to streamline processes, improve productivity, reduce costs, and adapt to evolving customer needs. No matter the type or scale of manufacturing, utilizing data effectively can lead to better decision-making and increased operational efficiency.

Data and Analytics Services for Manufacturing

We help manufacturers integrate and analyze their data to gain a complete view of their operations, from equipment to personnel, so they can make informed decisions that drive business success.

We help manufacturers maximize the value of their data by making it a valuable asset alongside their personnel, equipment, and systems responsible for production

Improve Supply Chain Visibility

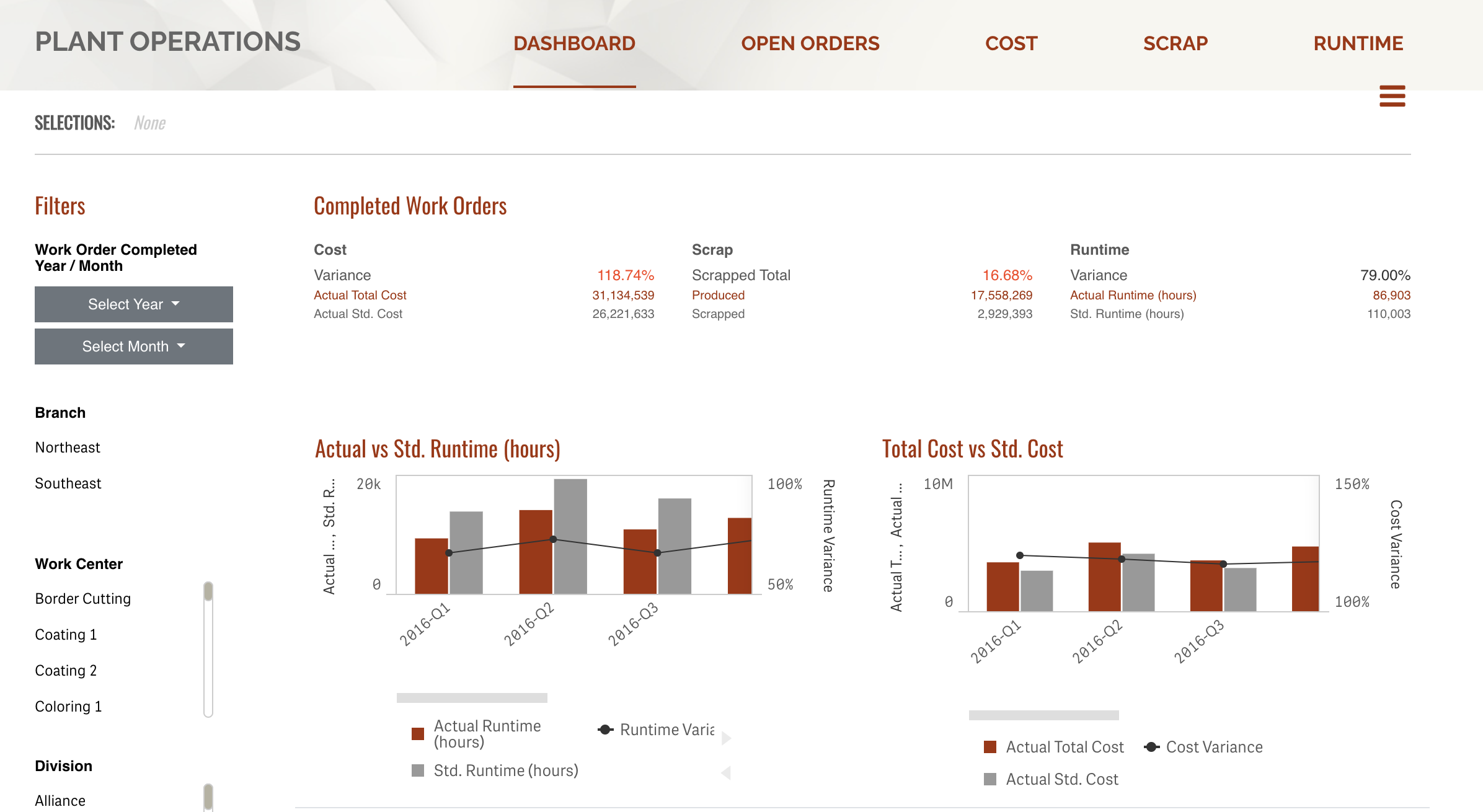

By integrating data from various software systems, including ERP, MRP, supply chain, and shop floor operations, we provide a comprehensive view of operations to enhance quality, efficiency, customer service, and productivity.

Optimize Production Lines

Achieve leaner, smarter, and more efficient operations by improving quality, performance, and cost, reducing machine downtime, and optimizing maintenance cycles.

Leverage Machine Learning and Advanced Analytics

Identify opportunities for machine learning and predictive analytics to predict risks, implement proactive equipment maintenance and settings, and enhance production levels and manufacturing quality.

Assess and Improve Quality, Efficiency, and Productivity

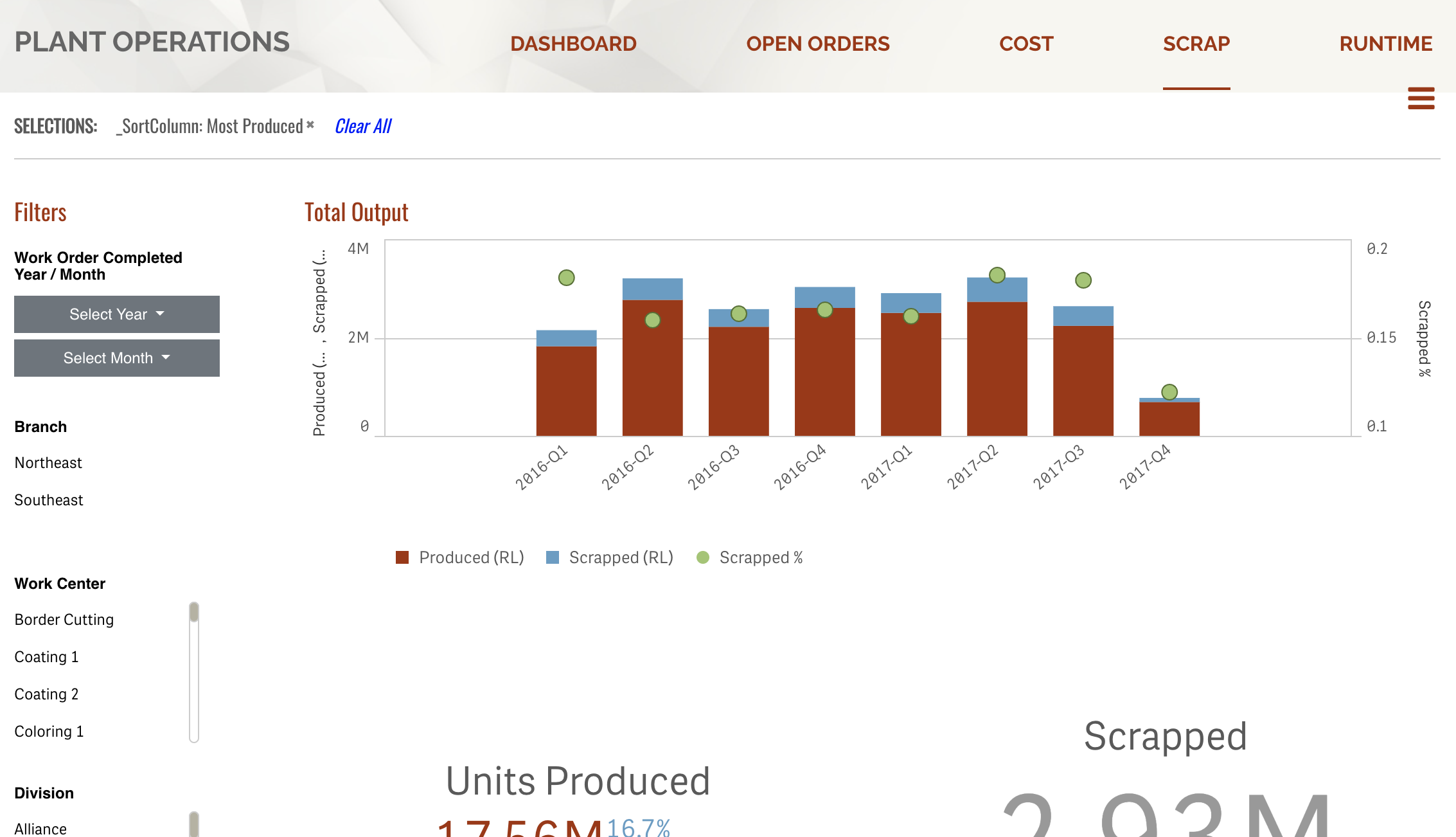

Monitor production metrics to optimize quality, throughput, and production planning, while measuring safety metrics, responsiveness to demands, and cost. With less time spent on reacting to issues, you can focus on data-driven improvements and lean initiatives.

Here are some examples of how a manufacturing company can use business intelligence (BI):

Supply chain management

Use BI to track inventory levels, optimize shipping routes, and monitor supplier performance.

Quality control

Analyze production data to identify patterns in defects and determine root causes. Use this information to improve quality control processes and reduce defects.Analyze production data to identify patterns in defects and determine root causes. Use this information to improve quality control processes and reduce defects.

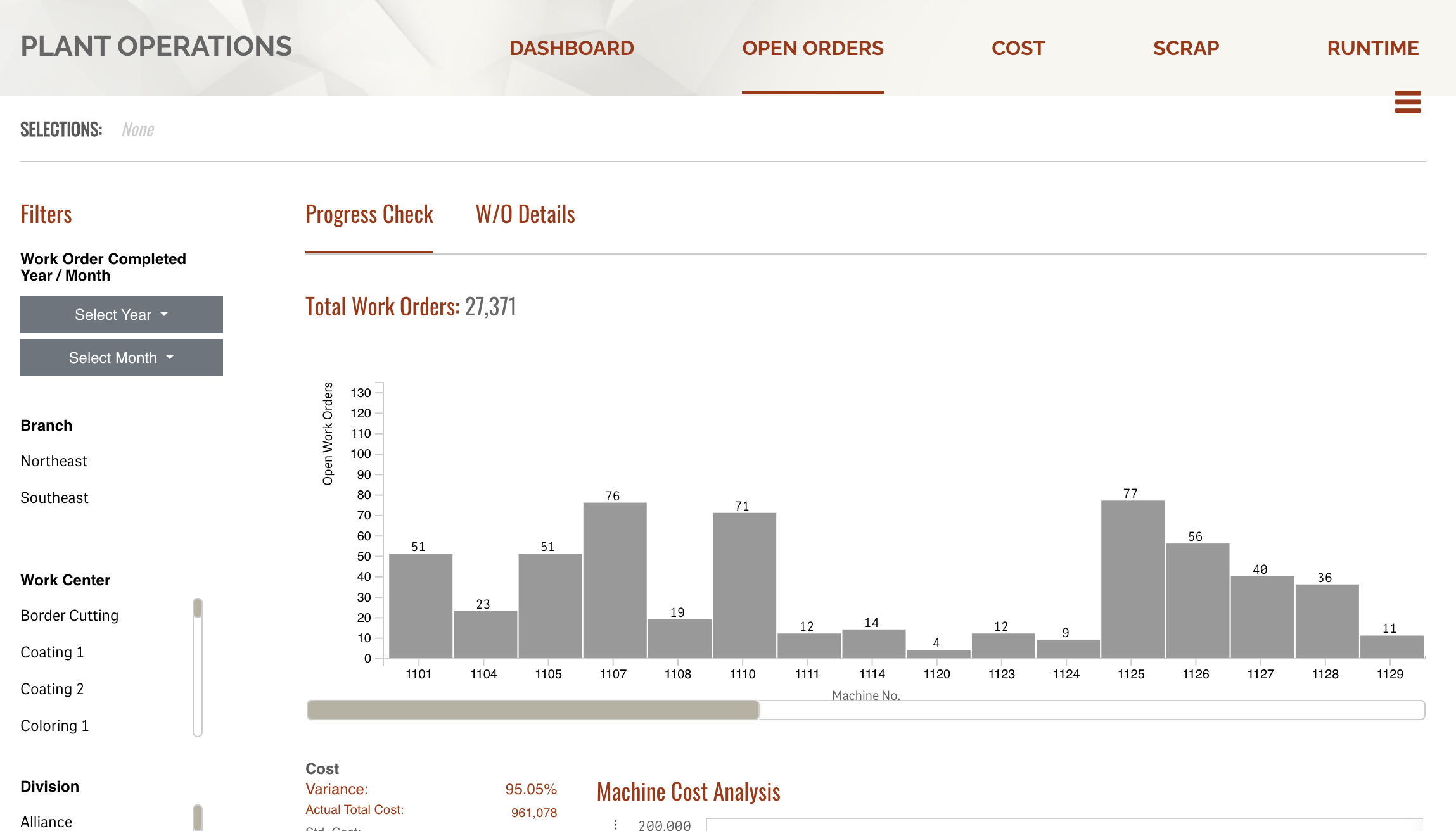

Production planning

Use BI to predict demand and optimize production schedules. This can help you avoid stockouts and reduce excess inventory.

Equipment maintenance

Use predictive analytics to forecast when equipment is likely to fail and schedule maintenance before a breakdown occurs.

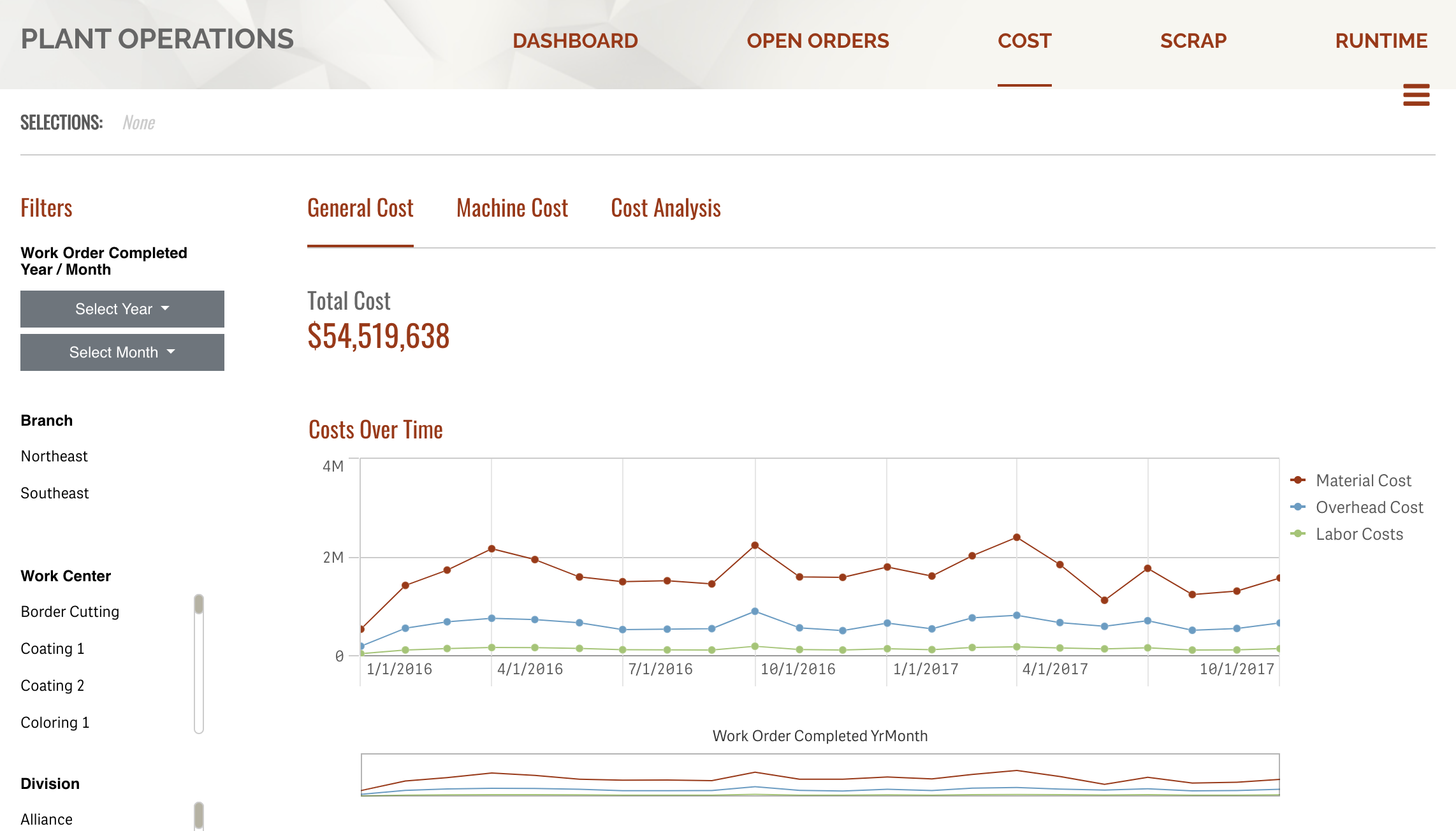

Cost control

Use BI to track expenses and identify areas where costs can be reduced. This can help you optimize production processes and increase profitability.